| Sign In | Join Free | My wpc-board.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My wpc-board.com |

|

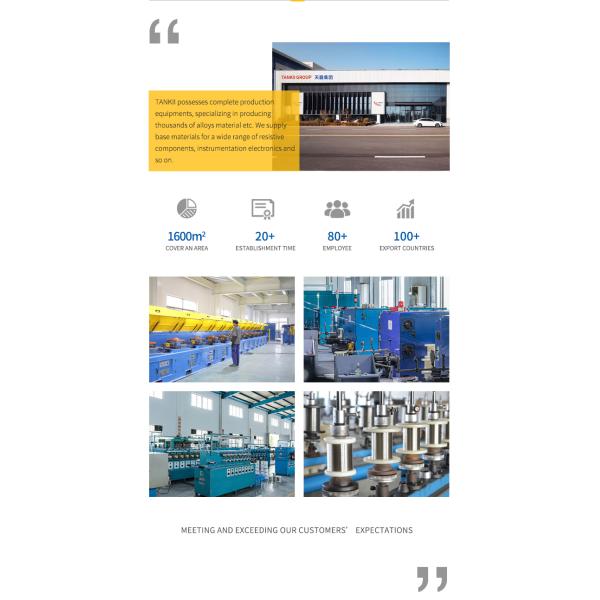

Brand Name : TANKII

Model Number : CuMn12Ni

Certification : ISO

Place of Origin : China

MOQ : 20kg

Payment Terms : T/T,L/C,Western Union

Supply Ability : 60,000kg/Month

Packaging Details : Wire diameter 0.02mm-1.0mm packing in spool, big than 1.0mm packing in coil

Price : 30USD/KG

Poissons Ratio : 0.320 (Calculated)

Strip Thickness : 0.01~6.0

Wire/Rod/Bar diameter : 0.02mm-30mm

Tensile Strength, Ultimate : 372 - 517 MPa

Machinability : 20% UNS C36000 (free-cutting brass) = 100%

Temperature Range : Suitable for use at temperatures up to 400°C (750°F)

CuNi10Fe1/C70600 Strip/sheet : Copper Nickels (Copper-Nickel), Copper-Nickel, (90-10)

Product Category : Copper Nickel Alloy Wire

Enameled Wire Copper Nickel Alloy Wire

Copper nickel alloy has low electric resistance,good heat-resistant and corrosion-resistant,easy to be processed and lead welded.

It isused to make the key components in the thermal overload relay,low resistance thermal circuit breaker, and the electrical appliances.

It is also an important material for electrical heating cable.

Size dimension range:

Wire: 0.05-10mm

Ribbons: 0.05*0.2-2.0*6.0mm

Strip: 0.05*5.0-5.0*250mm

CuNi series:CuNi1 (NC003), CuNi2(NC005), CuNi6(NC010), CuNi8(NC012), CuNi10(NC015), CuNi14(NC020), CuNi19(NC025), CuNi23(NC030),CuNi30(NC035), CuNi34(NC040), CuNi44(NC050).

| Product Type | UEW/180 | EIW/180 | EIW/AIW/200 | EIW/AIW/220 |

| IEC Guideline | IEC 60317-51 IEC 60317-20 | IEC 60317-23 IEC 60317-3 IEC 60317-8 | IEC 60317-13 | IEC 60317-26 |

| Temperature Index (°C ) | 180 | 180 | 200 | 220 |

| Softening Breakdown Temperature(°C) | 230 | 300 | 320 | 350 |

| Thermal Shock Temperature(°C) | 200 | 200 | 220 | 240 |

| Solderability | 390ºC/3s Solderable | Not weldable | Not weldable | Not weldable |

| General Description | 180Grade Straight Welded Polyurethane | 180Grade Polyester Imide | 200Grade Polyamide imide compound polyester imide | 220Grade Polyamide imide compound polyester imide |

| Type | Electrical resistivity (20degreeΩ mm²/m) | temperature coefficient of resistance (10^6/degree) | Density g/mm² | Max. temperature (°c) | Melting point (°c) |

| CuNi1 | 0.03 | <1000 | 8.9 | / | 1085 |

| CuNi2 | 0.05 | <1200 | 8.9 | 200 | 1090 |

| CuNi6 | 0.10 | <600 | 8.9 | 220 | 1095 |

| CuNi8 | 0.12 | <570 | 8.9 | 250 | 1097 |

| CuNi10 | 0.15 | <500 | 8.9 | 250 | 1100 |

| CuNi14 | 0.20 | <380 | 8.9 | 300 | 1115 |

| CuNi19 | 0.25 | <250 | 8.9 | 300 | 1135 |

| CuNi23 | 0.30 | <160 | 8.9 | 300 | 1150 |

| CuNi30 | 0.35 | <100 | 8.9 | 350 | 1170 |

| CuNi34 | 0.40 | -0 | 8.9 | 350 | 1180 |

| CuNi40 | 0.48 | ±40 | 8.9 | 400 | 1280 |

| CuNi44 | 0.49 | <-6 | 8.9 | 400 | 1280 |

|

|

Enameled Copper Nickel Alloy Wire 0.02mm-30mm for Electrical Heating Images |